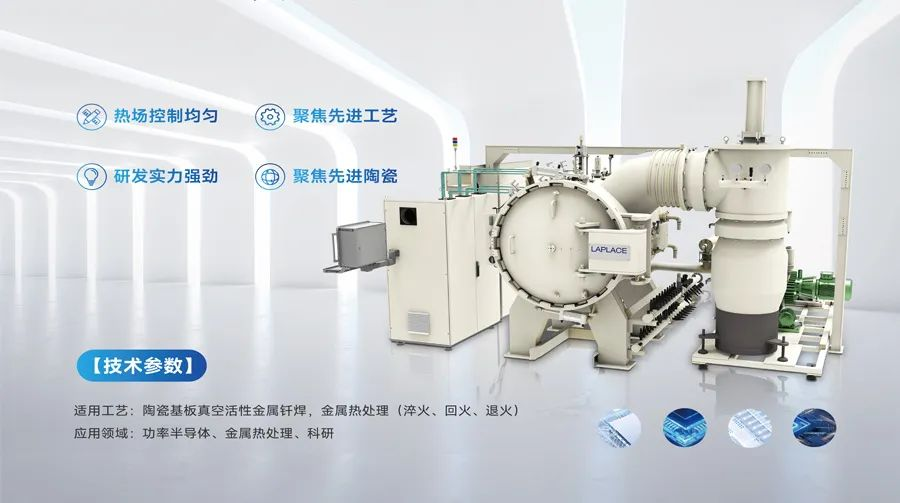

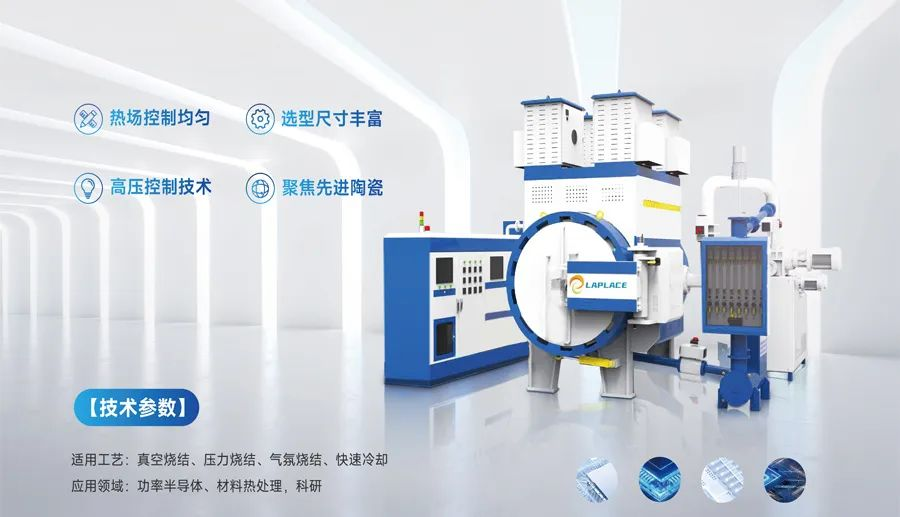

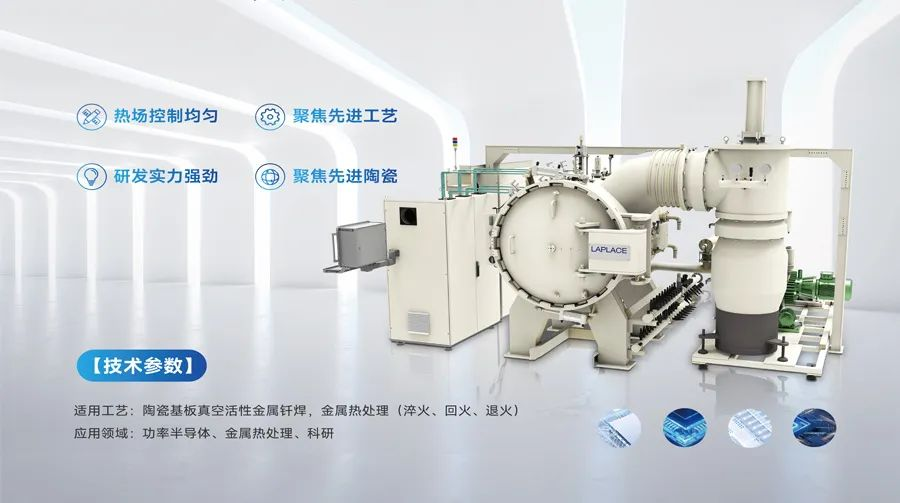

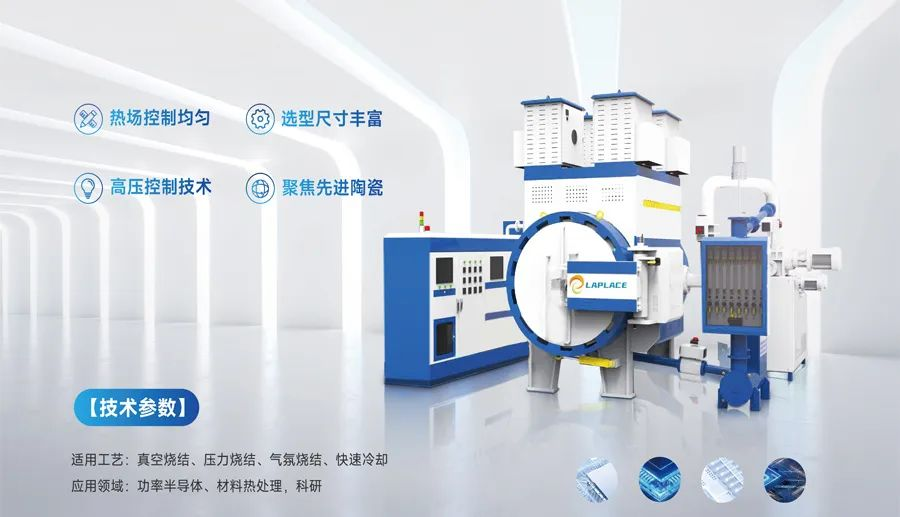

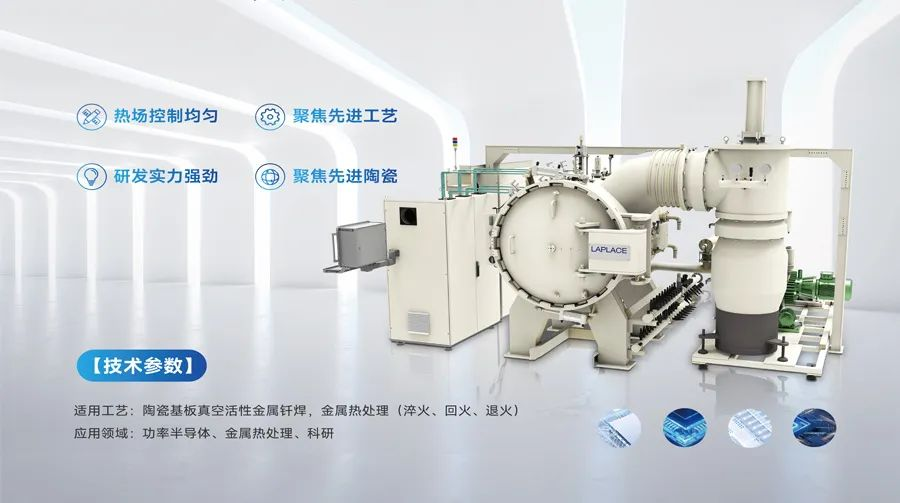

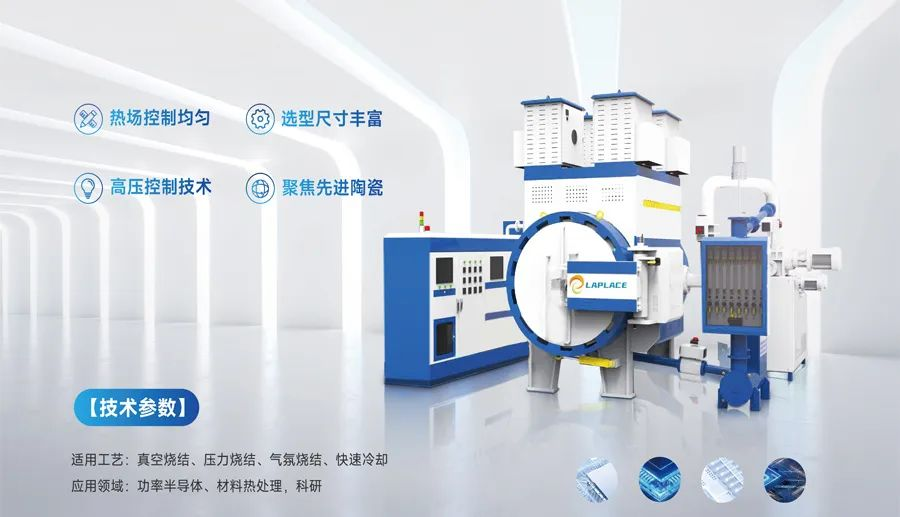

IACE CHINA 聚焦行业尖端产品技术 由新之联伊丽斯(上海)展览有限公司主办的 “中国国际先进陶瓷展览会” 将于 2024年3月6-8日 在上海世博展览馆隆重举办。展览内容涵盖先进陶瓷原料、机械设备、部件产品及服务等整条工艺链。展会规模达 45,000 平方米,云集 900+家 中外企业参展,同期会议论坛嘉宾演讲多达 100+ 场次,预计将吸引 65,000 名专业观众到场参观。 优质展商推介 拉普拉斯(广州)半导体科技有限公司 展位号: H1馆 A942 NEW 精彩展品 抢先看 01 Pindola TM 压力烧结炉HIP600 Pindola TM Pressure sintering furnaceHIP600 技术参数 Technical Parameter 适用工艺:真空烧结、压力烧结、气氛烧结、快速冷却 Process: Vacuum sintering, pressure sintering, atmosphere sintering 装料量:>400Kg(可定制)Max load capacity: >400Kg (customizable) 压力范围涵盖1MPa、2MPa、6MPa、10MPa。 The pressure range covers 1MPa, 2MPa, 6MPa, and 10MPa 应用领域 高温压力烧结炉广泛应用于陶瓷基板制造、先进陶瓷材料烧结等领域。不论您是从事研发还是批量生产,我们的设备都能助您实现高品质、高效率的制造过程。 High temperature pressure sintering furnace is widely used in ceramic substrate manufacturing, advanced ceramic materials sintering and other fields. Whether you are engaged in research and development or series production, our equipment enables you to achieve high quality and efficient manufacturing processes. 02 Pindola TM 真空钎焊炉LVD400 Pindola TM vacuum braze furnaceLVD400 技术参数 适用工艺:陶瓷基板真空活性金属钎焊,金属热处理(淬火、回火、退火)Application process: ceramic substrate vacuum active metal brazing, metal heat treatment (quenching, tempering, annealing) 应用装料量:>200Kg(可定制)Application loading capacity: >200Kg (customizable) 有效加热区:400×400×600(W×H×L)mm(可定制)Effective heating area: 400×400×600 (W×H×L) mm (customizable) 应用领域 广泛应用于陶瓷基板制造、电子器件封装、传感器制造等领域,帮助客户实现高质量、高效率的生产过程。 It is widely used in ceramic substrate manufacturing, electronic device packaging, sensor manufacturing and other fields to help customers achieve high quality and efficient production process. 03 Bhadra TM 脱脂炉 Bhadra TM Debinding furnace 技术参数 适用工艺:陶瓷及金属材料的多种烧结工艺,实现产品氮化铝基片、氮化硅基片的排胶。 Application process: A variety of sintering processes of ceramic and metal materials, to achieve the product of aluminum nitride substrate, silicon nitride substrate strip. 有效加热区:820×700×1100mm (L×W×H)mm(可定制)Effective heating area: 820×700×1100mm (L×W×H)mm (can be customized) 温度范围:RT~1000℃; Temperature range: RT~1000℃ 应用领域 我们的脱脂炉广泛应用于半导体、光电子、微电子等领域都发挥着关键的作用,确保基片表面的清洁度和质量,从而提高制备的器件性能。 Our degreasing furnaces are widely used in semiconductor, optoelectronics, microelectronics and other fields and play a key role in ensuring the cleanliness and quality of the substrate surface, thereby improving the performance of the prepared devices. 04 Pindola TM 链带式烧结炉 &氧化炉 Pindola TM Chain belt sintering f urnace&oxidation furnace 产品简述 适用工艺:主要用于各类金属材料的预氧化、DBC陶瓷覆铜高温烧结等热处理设备。 Application process: Mainly used for pre-oxidation of various metal materials, DBC ceramic copper coating high temperature sintering and other heat treatment equipment. 网带宽度范围:200mm、400mm等(可定制)Net belt width range: 200mm, 400mm, etc. (can be customized) 温区范围8、10、16(可定制)Temperature range 8, 10, 16 (customizable)aa 应用领域 DBC烧结炉在需要高温热处理和金属陶瓷结合的应用中具有广泛的应用前景,涵盖了电子行业、能源领域、汽车、电子航空航天和医疗设备等多个重要领域。 DBC sintering furnaces have a wide range of applications requiring high-temperature heat treatment and the combination of cermet, covering many important areas such as the electronics industry, energy field, automotive, electronic aerospace and medical equipment. 05 Pindola TM 卧式预氧化炉 Pindola TM horizontal pre oxidation furnac 技术参数(TechnicalParameter)适用工艺:陶瓷基板铜片或其他基材预氧化 Applicable process:Pre oxidation of ceramic substrates, copper sheets or other substrates 应用载片量:≥300PCS(可定制)Applicationloadingcapacity:>300PCS(customizable) 恒温区:≥1700mm(可定制)Flatzonelength:≥1700mm(customizable) 主要特点 采用周期式生产方式,有效提高产能,同时能够有效减小占地面积并降低能耗。具备精确的温度和气体流量控制功能,确保批内及批间产品的稳定性和可重复性,从而产生高质量的氧化层。配备友好的界面和智能化控制系统,使操作简单、方便。 Adoptingacyclicalproductionmethodcaneffectivelyincreaseproductioncapacity,whilealsoreducingfootprintandenergyconsumption.Equippedwithprecisetemperatureandgasflowcontrolfunctions,ensuringthestabilityandrepeatabilityofproductswithinandbetweenbatches,therebyproducinghigh-qualityoxidelayers.Equippedwithauser-friendlyinterfaceandintelligentcontrolsystem,makingoperationsimpleandconvenient. 关 于拉普拉斯 拉普拉斯(广州)半导体科技有限公司是拉普拉斯新能源股份有限公司的全资子公司,集团公司成立于2016年,是由多位海内外半导体设备领域高端人才创立的高端装备研发制造企业。拉普拉斯致力于成为泛半导体领域领先的国产高端制造装备与解决方案提供商。 拉普拉斯现有雇员超过3500人,公司拥有一支包含多名外籍专家和多名博士在内的核心研发团队,技术人员占比超过40%。目前公司拥有超过600项专利申请,发明专利申请超过150项,被工信部认定为国家级专精特新“小巨人”。 拉普拉斯(广州)半导体科技有限公司核心产品以半导体镀膜和热处理设备为主,其中陶瓷基板真空钎焊炉和压力烧结炉、脱脂炉、DBC烧结炉&氧化炉应用领域集中在陶瓷基板相关生产制程,并获得国内多家客户上线验证和量产订单。 Laplace (Guangzhou) Semiconductor Technology Co., Ltd. is a wholly-owned subsidiary of Laplace New Energy Co., Ltd., which was founded in 2016, is a high-end equipment R&D and manufacturing enterprise founded by many high-end talents in the field of semiconductor equipment at home and abroad.Laplace is committed to becoming a leading domestic high-end manufacturing equipment and solutions provider in the pan-semiconductor field. Laplace has more than 3500 employees, and the company has a core R&D team including many foreign experts and doctors, with technical personnel accounting for more than 40%. At present, the company has more than 600 patent applications, and more than 150 invention patent applications.LAPLACE has been recognized by the Ministry of Industry and Information Technology as a national-level Specialized, Refined, Differential and Innovative “Little Giant”. Laplace (Guangzhou) Semiconductor Technology Co., Ltd. core products to ceramic substrate vacuum brazing furnace and pressure sintering furnace, degreasing furnace, DBC sintering furnace & oxidation furnace, application fields focused on ceramic substrate related manufacturing, and obtained online verification and mass production orders from many domestic customers. 地址: 广州市黄埔区瑞泰路2号 Add: #2, Ruitai Road, Huangpu District, Guangzhou 电话/Tel: 020-3156 9374 邮箱/Email: sales-semi@laplace-tech.cn 官微 加入群聊