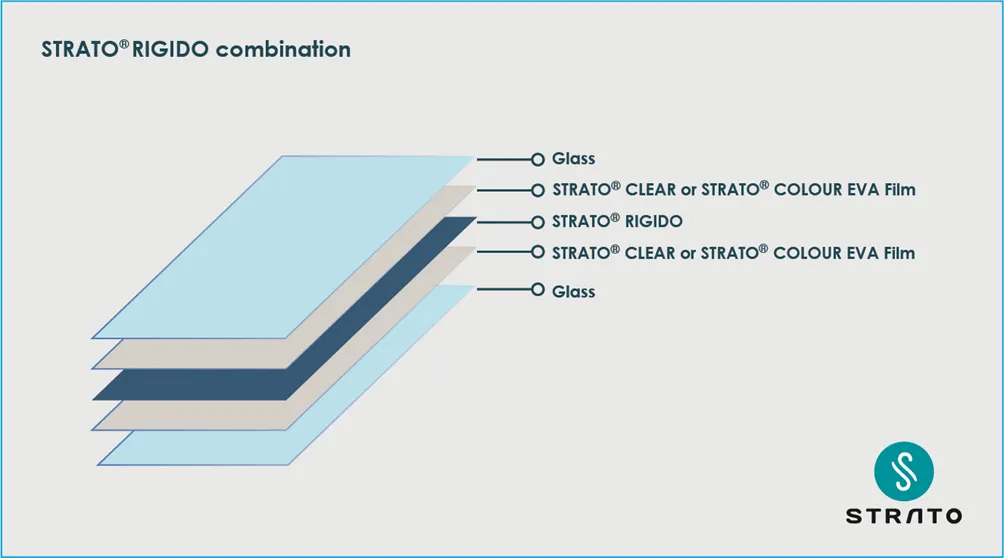

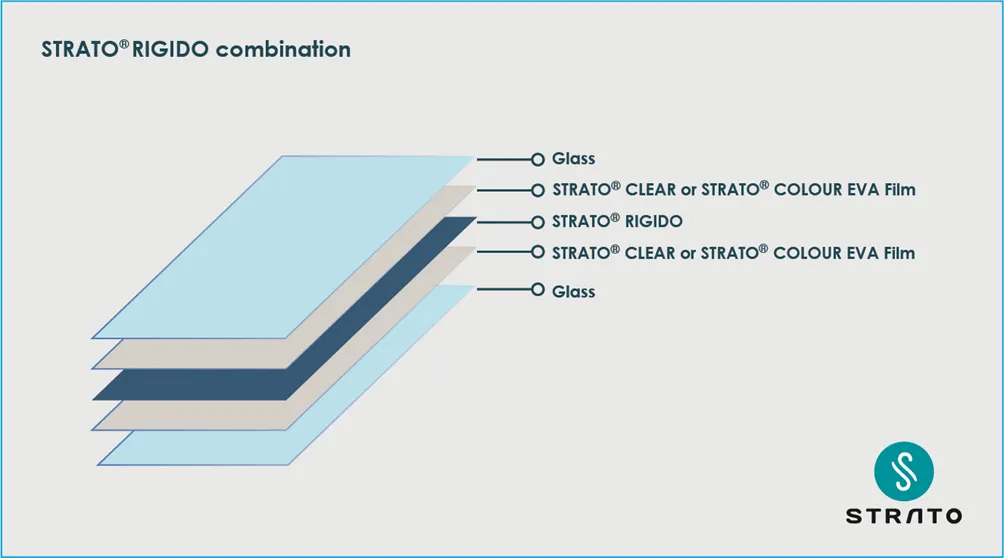

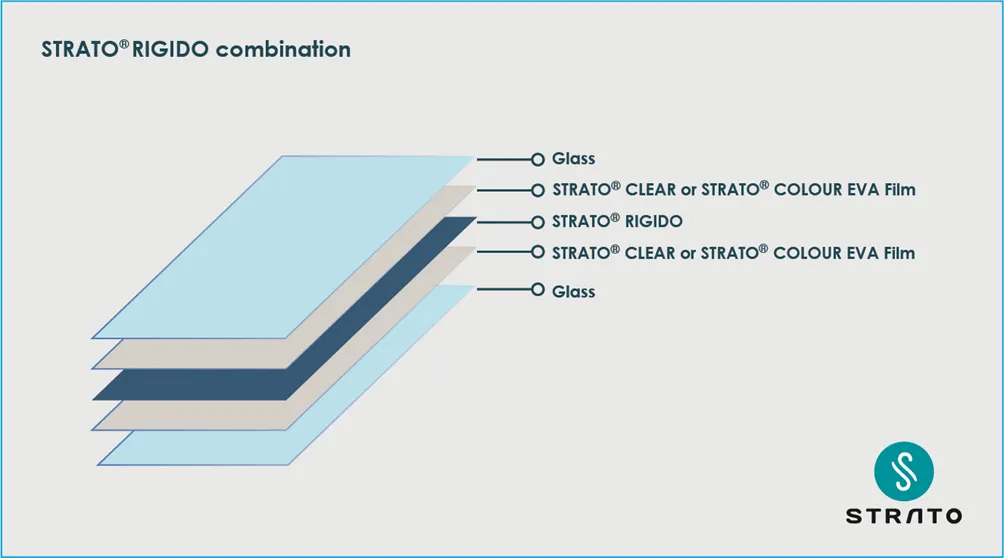

企业介绍 展位号: N1-193 SATINAL Spa Satinal, Italian Ecosystem for Safety Glass Manufacture. Visit Satinal booth N1- 193 / China Glass Exhibition. STRATO® is an European leader in EVA film manufacturing for glass lamination. It offers: 🔹 a wide range of colours and finishings 🔹 different sizes to reduce waste and to save costs 🔹 fast delivery 🔹 worldwide shipment and technical support Smoothness and elasticity with STRATO® Clear, the non-plus-ultra EVA film for the architectural glass market. Among its features: 💎high transparency properties 🌿natural and neutral looking 🔈 great sound insulation performance 🤝compatible with a wide range of inserts Colours are a window to the soul. They express emotions and convey unique feelings. With our STRATO® COLOUR product range , we bring you the perfect solution to meet your indoor and outdoor needs, offering new and refined aesthetic design solutions. What are the main advantages? 🔹 Indoor and outdoor applications 🔹 Safety glass applications 🔹 Acoustic insulation 🔹 Colour uniformity 🔹 UV protection 🔹 Resistance to external factors, such as humidity STRATO® EVA interlayer is the winning choice for laminated glass. With its thermosetting chemical composition, STRATO® EVA film ensures maximum safety in case of glass breakage, filters up to 99% of UV rays, and provides a great sound insulation. Its durability is guaranteed by the high level of resistance even to exceptional climatic conditions, such as high temperatures, high humidity and extreme weather conditions. Discover the experience of Satinal Team by choosing STRATO® EVA product range. STRATO® RIGIDO is a special structural interlayer that ensures one of the highest levels of protection against strong impacts . Even if the glass component breaks, the laminated structure is not weakened, so the stability and safety of the product are preserved. STRATO® RIGIDO is the best solution when safety and stiffness are mandatory, like in buildings, canopes, ceilings, floors, facades and more. STRATO® RIGIDO must be laminated with two sheets of STRATO® EVA film , so the mechanical, adhesive and optical properties can be achieved. STRATO® EVA , that ensures the adhesion of STRATO® RIGIDO to glasses, is a thermosetting material . Differently from PVB film, it creates three-dimensional bonds at molecular level during the lamination process, making STRATO® EVA laminated structurally safe. The great mechanical properties of STRATO® EVA combined with the stiffness of STRATO® RIGIDO allow to laminate any thickness of glass , guaranteeing the same structural loading any time and over time. Open edges applications STRATO® RIGIDO is not a hygroscopic material and therefore does not fear moisture . Moreover, STRATO® EVA film is not sensitive to humidity, water, temperature fluctuations and more: that is why STRATO® product range is compatible with indoor as well as outdoor applications without the risk of delamination. So, no worry to install STRATO® EVA laminated glasses at the most extreme weathers. Multilayer combinations: what does it mean? Safety and stiffness are mandatory when it comes to project buildings, canopes, ceilings, floors, facades and more. It is clear that the combination of safety and stilying is definitely possible with STRATO® product range. STRATO® RIGIDO must be assembled inside two sheets of STRATO® EVA and two panes of glasses, but multiple combinations are still possible. Here below two inphographic examples that easly explain how panes of glass can be combined with multiple sheets of STRATO® RIGIDO and STRATO® EVA films, meeting the approval of architectural guidelines in terms of structural safety. Dimensions, thickness and length . Last but not least, dimensions are important. That is why STRATO® RIGIDO is available in different formats, width, thicknesses and roll lengths. TK is an Italian Company based in a highly technological area, where expertise and production, all together, create excellent results. TK is an Italian leader specialized in the design and construction of plants and ovens for glass lamination, temper, chemical temper and Heat Soak Test. TK technical department designs all the ovens that are tailor-made and manufactured by working closely with customers to understand and meet their needs. TK uses only the best Italian technology and European components to achieve the quality standards they have set themselves. TK offers high quality, safe and efficient products and an excellent customer care service to the clients, thanks to a continuous investment on research and development, and testing the quality and efficiency of the products. Tkare values: / Aligning customers’ requirements / Defining bespoke solutions / Designing and developing the equipment / Manufacturing the machinery / Performing delivery and installation / Training staff / Providing after-sales on-site and remote assistance TK Worldwide: TK is a high-profile company, extremely reliable and characterized by a high level of technology and innovation with a strong presence throughout the world. Over the years more than 270 plants have been installed and has been created a solid customer network in over 60 countries. 扫 描 二 维 码 关 注 第33届中国玻璃展 玻璃展 注册参观更便捷 本文刊登的材料(包括文字、图片、视屏等),未经许可不得复制。如有疑问请与后台工作人员联系。 我们已尽责核对所提供信息,但对信息的及时性和准确性不作任何担保。涉及信息、产品或服务(包括第三方信息、产品或服务)的材料均按照展商提供进行格式编辑,我们不提供任何担保,不保证其质量满意、适合特定用途或不侵权,不保证其兼容性、安全性及准确性。材料中链接指向其他网址,旨在方便您了解更多信息。不表示我们认可该网址。对于链接网址的内容,我们不承担任何责任。注册活动时,您个人资料的搜集、处理和使用将按照相关数据保护规定办理。